To meet the various industrial needs of gases, you need a continuous supply. If your machines are running on them, you cannot afford to lose them in between. A single day or a few hours of shortage lead to a complete blockage in many cases. For example, in cases like medical and emergency, there must always be enough supply of oxygen cylinders. You cannot predict any emergency and therefore the suppliers must be able to take care of any such situations too. Then, you have the other businesses like mining sector. The raw material cannot be disregarded or else their production and work will be hindered.

As we mentioned above, these gases like nitrogen and oxygen come in easy to carry containers or cylinders of various sizes. They also come in large quantities filled in tankers, and, they are also generated right on the spot using nitrogen generation systems, for example, these converts from other sources and produce nitrogen gas at a given pressure and purity. The output depends on the use of it. Mostly, it is not used directly, but mixed further for other purposes. One of the uses of nitrogen is for creating low-temperature environments for keeping things cool. Such systems are big and small based on standard norms. And, they can also be built according to custom requirements right at the spot. Many companies today in Australia take up orders for providing designing and building such systems. This facilitates a lot of other tasks in the row. It reduces the dependency on importing such machines, for one thing.

Then, having local suppliers taking care of such use cases improves reliability.Offering on-demand gas supplies right from the source with a simple call is what you can expect now. Just like ordering for a water tanker, you can call for emergency gas requirements. There are agencies that take up both retail and large-scale turnkey gas generation system orders across Australia, New Zealand. It has greatly improved the efficiency and reduced the costs incurred previously when importing them from countries like the USA. Servicing was also a problem.

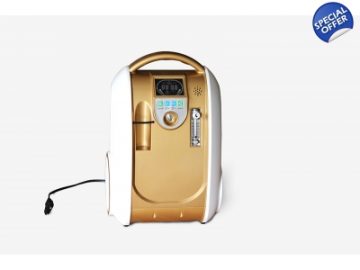

The same can be said about the oxygen machine too. Just like these systems, it can also be produced right on the spot. This improves the reliability. For example, in oil and gas mining industry, fresh oxygen is always required for breathing condition for workers. In those cases, oxygen is freshly prepared and slightly mixed with other gases and prepared for breathing. This is more cost effective than buying cylinders every day.